Design Advantages of FV Oil Film Bearings on High Speed Wire Rod mill

The High-speed wire rod mill is the key equipment in the steel industry production line, which lays the rolled wire rod into coils for easy collection. The position of the High-speed wire rod mill is after the finishing mill, and its function is to wind the wire into a coil of a certain diameter, and then lay it flat on the roller table. The quality of the coils spit out by the High-speed wire rod mill has a great influence on the subsequent processes such as winding and packing, especially on the appearance of the product after packing. The High-speed wire rod mill is generally composed of a transmission device, a hollow shaft, a laying disc, a laying tube, a bevel gear and other components. Today we will discuss the bearing of High-speed wire rod mill.

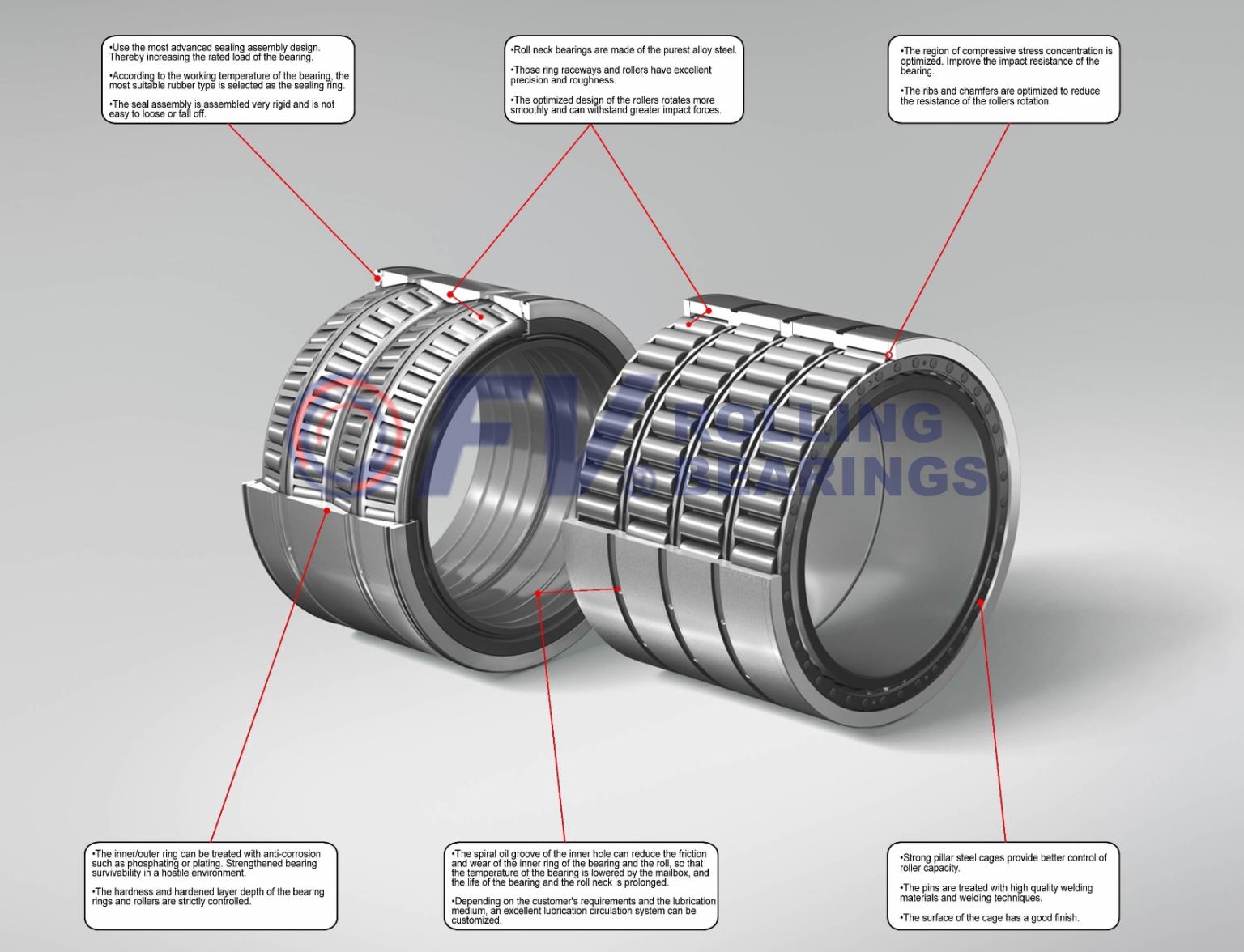

In the traditional technology, rolling bearings are generally used for High-speed wire rod mill. Rolling bearings are reliable, easy to use and maintain, have good starting performance, and have high bearing capacity at medium speeds. However, the vibration and noise of rolling bearings are relatively large during use, especially in the later period of use. Moreover, rolling bearings are particularly sensitive to foreign objects such as metal chips. Once foreign objects enter the bearing, intermittent large vibration and noise will occur, and early damage to machinery and equipment will also be caused. At the same time, the service life of rolling bearings is often short. Therefore, oil film bearings are the best choice for occasions where high precision is required and no vibration is allowed.

The oil film bearing supports the rotating shaft by a smooth surface, so the contact part is one surface; the movement mode of the oil film bearing is sliding, so the friction situation is completely different. Oil film bearing sliding surfaces are separated by lubricating oil without direct contact. Oil film bearings work smoothly, reliably and without noise. It can also greatly reduce friction loss and surface wear, and the oil film also has a certain ability to absorb vibration.

FV, as a Chinese manufacturer of oil film bearings, has a lot of research and production experience in oil film bearings in recent years. Mainly have the following advantages:

1.The oil film bearing adopts high-quality babbitt alloy as the base body, and adopts a special process for three-layer electroplating. It has the advantages of accurate coordination, quiet operation and low friction. The tin-plated layer can effectively prevent corrosion and reduce sliding resistance. FV oil film bearings are designed according to the principles of fluid mechanics. During rotation, an oil film is covered between the bearing body and the bearing housing by the lubrication system. The stress-free bearing sleeve has oil grooves to ensure even distribution of the oil. Ultra-high manufacturing precision enables oil film bearings to have excellent fatigue resistance, load carrying capacity and thermal conductivity, and a low coefficient of friction. Good corrosion resistance, embedment and compliance. Effectively solve the burning phenomenon such as the failure of the clamping pad and the falling off of the babbitt alloy. They are also compatible with other manufacturers' wire rod mills. Oil film bearings can be used directly on existing equipment without any design or mechanical changes.

2.Seal: FV oil film bearing mainly adopts double lip seal, which is mainly made of hydrogenated nitrile butadiene rubber (HNBR), and is formed in scientific proportion with other special raw materials. The metal support ring is made of high quality imported steel, which is carefully cut, ground and welded. As a result, new performance breakthroughs have emerged. In this way, better sealing performance can be obtained, the compression deformation can be reduced by 15% (running at 150°C for 24 hours), and the lubricating oil in the oil film bearing cavity and external cooling water, rolling oil, iron filings, dust and other impurities can be effectively sealed. At the same time, wear resistance and service life are significantly improved. Practice has shown that after 1-2 months of strict use, the seal has no obvious wear. Such a sealing design also has high temperature adaptability. Practice has proved that it can fully meet the performance requirements of the existing 120m/S high-speed rolling mill.

3. Elastic washer: The elastic washer is mainly used for the roller shaft of the roll box of the high-speed wire rod finishing mill and the transmission shaft of the transmission box. It is required to withstand high temperature and withstand the axial pressure of the center of the circle. The rubber in it must maintain a special torque resistance to allow the gasket to stretch within a certain range without the rubber sheet falling off. FV elastic washers are made of specially formulated rubber sheets and steel sheets on both sides, which are bonded by a special process. It can effectively absorb the impact force in the working process, adjust the parallel gap between the rolling bearings at one end, ensure the smooth operation and shock absorption of the equipment, and prevent the bearings from cracking or bumping.

The above are some of the advantages of Luoyang FV oil film bearings. If you have any oil film bearing require, please contact us - FV, professional Morgan bearing China OEM manufacturer.

Scan the QR code and push it to your mobile phone for access.

Copyright statement: This article is published by BLOG - FV BEARING INDUSTRIES, if you need to reprint, please indicate the source.