The role of lubrication and sealing of rolling bearings

As we all know, bearings are an important part of many mechanical equipment. The main function is to support and rotate equipment. A good quality rolling bearing can reduce the friction during the movement to the greatest extent and ensure its rotation accuracy.

Bearings are divided into rolling bearings and sliding bearings. In terms of the function of the bearing, it is used to carry the shaft, but this is only part of its function. The essence of the support is to be able to bear radial load or axial load. It is a fixed shaft that allows it to only rotate and controls its axial and radial movement. Without the bearing, the motor cannot rotate because the shaft can move in any direction, and the bearing drives the drive. In particular, the bearings of high-speed shafts should be well lubricated. Some bearings have been lubricated before installation, called pre-lubricated bearings. When the bearing is running at high speed, friction will not only increase energy consumption, but more importantly, it is easy to damage the bearing. Therefore, it is necessary to ensure that the lubrication condition of the bearing is good when it is running.

When it comes to lubrication, the purpose of bearing lubrication is to reduce the internal friction and wear of the bearing, prevent burning and sticky damage, and prolong its service life. The lubrication methods of bearings are divided into grease lubrication and oil lubrication. In order to make the bearing perform better, it is necessary to choose a suitable lubrication method by comparing the advantages and disadvantages of grease lubrication and oil lubrication. Pay particular attention to the amount of lubrication, whether oil or grease. If the amount is too small, insufficient lubrication will affect the life of the bearing, and too much amount will cause great resistance and affect the speed of the bearing.

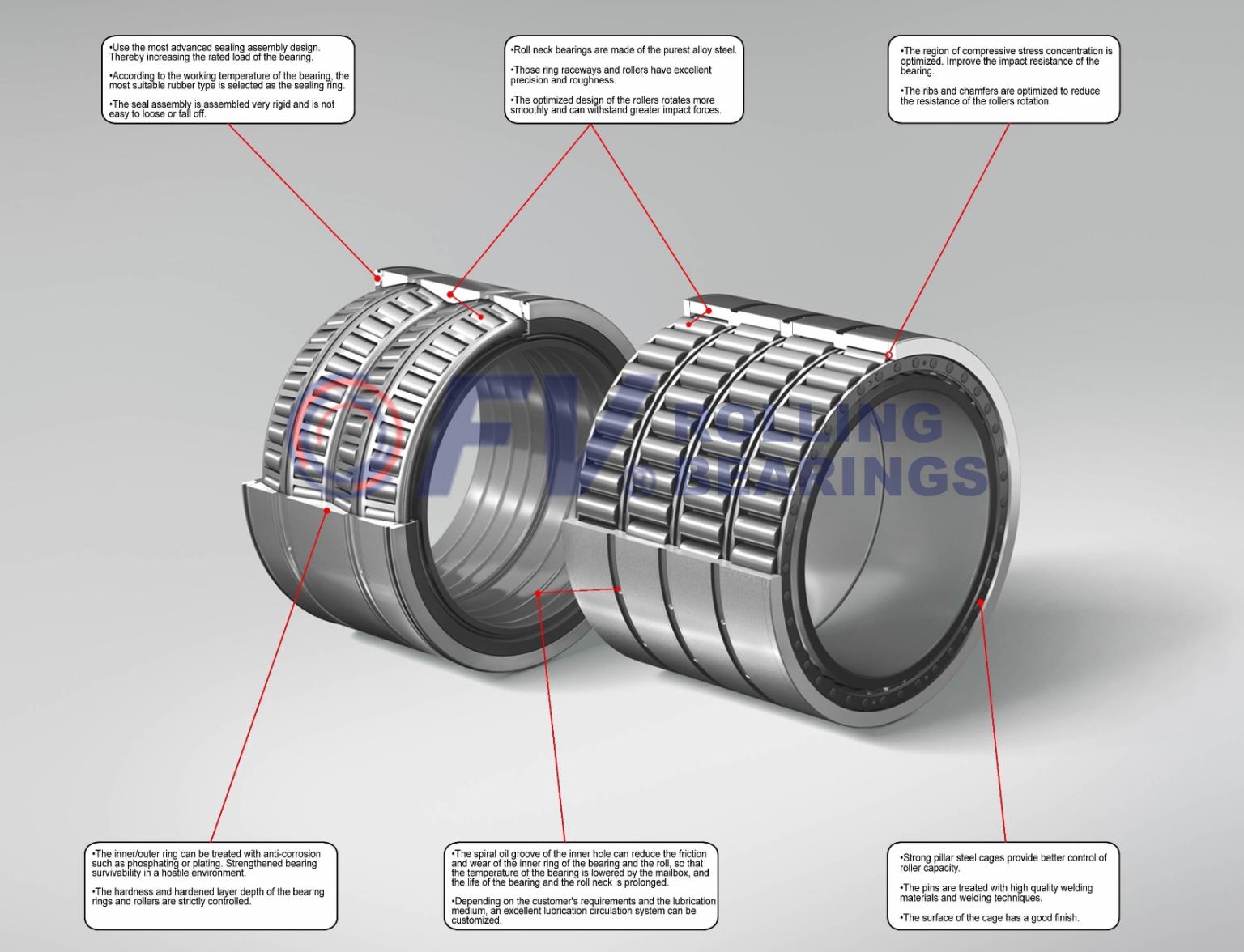

After lubricating, it is also necessary to ensure that the lubrication is not contaminated. This refers to the sealing of the bearing. Bearing seals can be divided into two types: self-sealing and external sealing. The so-called self-sealing is to make the bearing itself a device with sealing performance. For example, the bearing is equipped with a dust cover or a sealing ring, which occupies a small space, is easy to install and disassemble, and has a low cost. Adding a sealing device to the bearing is a sealing device with various properties manufactured inside the installation end cover. The external sealing of the bearing can be divided into non-contact sealing and contact sealing. Among them, non-contact sealing is suitable for high-speed and high-temperature occasions. Labyrinth, gasket and other different structural forms, the contact seal is suitable for medium and low speed conditions, and the commonly used structures include felt seals and cup seals.

Customers should choose the suitable bearing type, suitable lubricating grease and suitable seal according to their specific working conditions, so as to ensure the best use effect of the bearing.

Scan the QR code and push it to your mobile phone for access.

Copyright statement: This article is published by BLOG - FV BEARING INDUSTRIES, if you need to reprint, please indicate the source.

本文链接:https://blog.fv-bearing.com/Blog/The role of lubrication and sealing of rolling bearings/