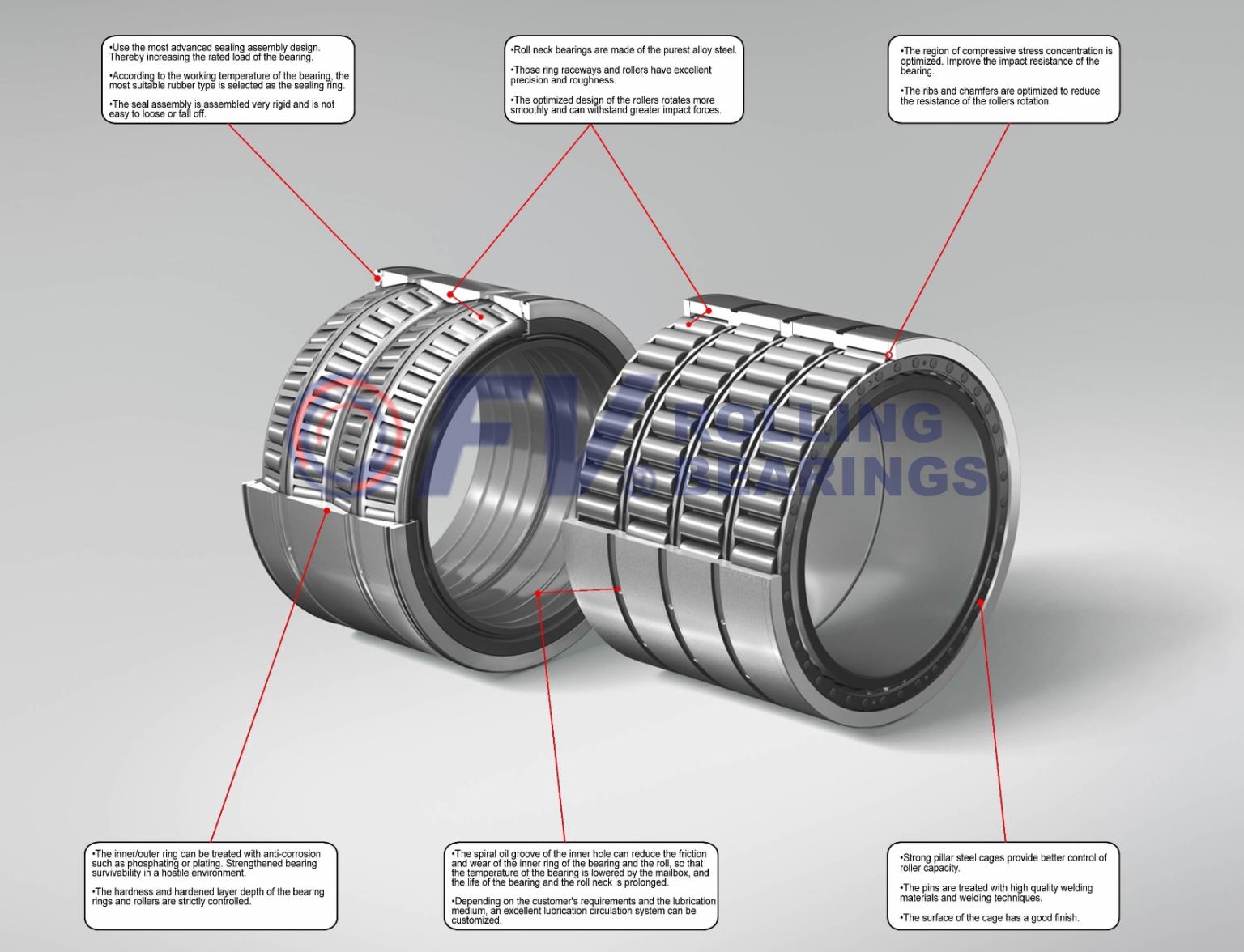

It is important to ensure operation of high speed wire rod mills bearings

In recent years, China's heavy industry has developed rapidly, and various advanced machinery and equipment have also been developed. At present, the domestic high-speed wire rod mills are also very advanced with high precision, and the quality of the wire rod mills produced is very high. There are more and more parts that can be matched. Among them, rolling mill bearings are very important components, occupying a very high position in the equipment parts market. Today, Luoyang FV will teach you how to judge whether the roll neck bearing is running well.

First of all, we can judge by the vibration of rolling mill bearings. Once the high-speed wire rolling mill bearing fails, its vibration will naturally change with it. Therefore, we must improve the inspection efforts in this area, so that abnormal vibration can be detected as soon as possible and corresponding solutions can be taken to minimize the reduction and downtime losses. Because the bearing is generally damaged in the process of working, and if the damaged part encounters disharmonious vibration, the peeling phenomenon will occur, so we can know whether the bearing is running normally through this phenomenon.

Secondly, it can also be judged by the bearing temperature of the high wire rolling mill. Normal bearing operation tends to maintain a constant temperature. If there is an abnormal increase, it means that the bearing must be abnormal. Therefore, be sure to pay attention to the temperature of the bearing during use.

Of course, the above is just a simple judgment method. If you are not sure about the use of the bearing in the process of using the rolling mill bearing, you can consult us.

Scan the QR code and push it to your mobile phone for access.

Copyright statement: This article is published by BLOG - FV BEARING INDUSTRIES, if you need to reprint, please indicate the source.