Three Simple Analysis Methods of Slewing Bearing Failure

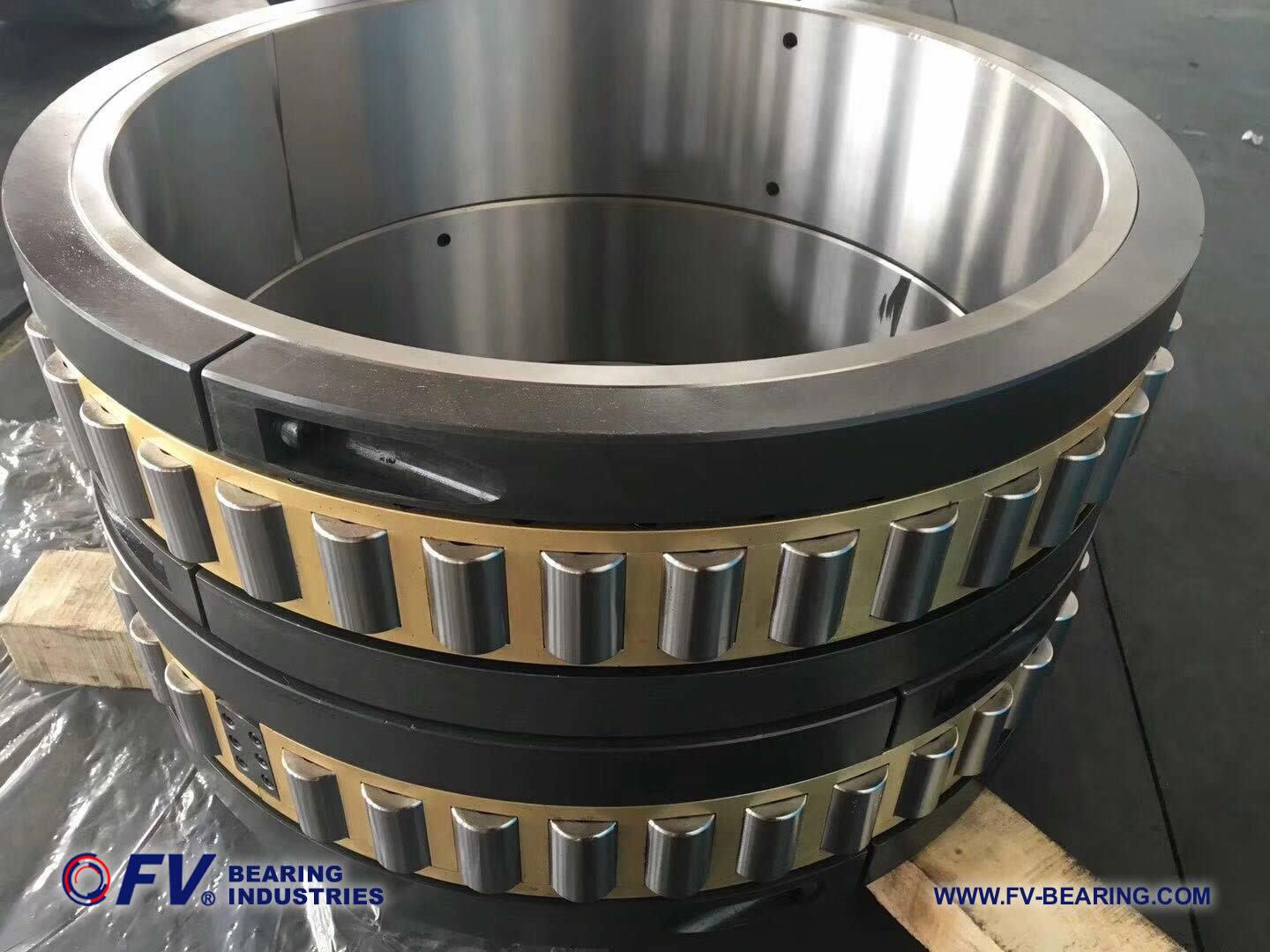

Slewing bearing is one of the indispensable parts in mechanical equipment, and it is generally large in size. There are also small size, thin and light series of slewing bearings. Mainly used in construction machinery. If the slewing bearing fails, it will lead to poor operation of the entire mechanical equipment, affecting production efficiency and quality. Therefore, it is necessary for users to discover and deal with some faults of the slewing bearing in time. So, do you know how to identify the failure of the slewing bearing?

Three methods for identifying slewing ring bearing faults

1. Lubricant identification method. The failure of the slewing bearing can be identified by the state of the lubricating oil. You can take some lubricants for analysis, observe the degree of contamination, and judge whether foreign matter is mixed. If the slewing bearing cannot be observed at close range, this method can be used.

2. Identification by temperature. Identifying by the working temperature of the slewing bearing belongs to the comparative identification method, because it is necessary to compare the temperatures recorded before and after. This method is mainly used in the workplace where the operating state of the slewing bearing does not change much. Therefore, it is necessary to record the temperature continuously. When the slewing bearing fails, the temperature will rise and change irregularly. When the temperature changes abnormally, it is very likely that there is a problem with the slewing bearing.

3. Voice recognition method. The failure of the slewing bearing can be identified by sound, but this method requires the inspector to have rich experience and sufficient training to recognize the sound of the slewing bearing and the sound of the non-slewing bearing. For this reason, we should try to assign someone to do it. In this work, the sound of the slewing bearing can be clearly heard by pasting a listening device or a listening bar on the shell, and the problem can be judged by different sounds.

The above are just some simple methods. If you don't have enough experience, you are likely to make mistakes. Another very safe method is to disassemble the slewing bearing and use a special measuring instrument for testing. If there are no special measuring instruments and inspectors, the above three methods can be used.

Of course, another method is to consult a specialized rolling bearing manufacturer. Luoyang FV is a professional bearing supplier. Our engineers are always waiting to serve you.

Scan the QR code and push it to your mobile phone for access.

Copyright statement: This article is published by BLOG - FV BEARING INDUSTRIES, if you need to reprint, please indicate the source.

本文链接:https://blog.fv-bearing.com/Blog/Three Simple Analysis Methods of Slewing Bearing Failure/