Discussion on the Characteristics of Morgan High Speed Wire Rolling Oil Film Bearings

As we all know, the characteristics of high-speed wire rod mills are high speed and heavy load, which are difficult to bear with rolling bearings, and sliding bearings are the most ideal choice. Oil film bearings are parts and components that belong exclusively to the metallurgical industry and the field of high-speed wire rod mills. For people in other fields, they may not have heard of oil film bearings. Sliding bearings use lubricating media to reduce friction, thereby reducing wear caused by friction. The greater the viscosity of the lubricating medium, the stronger the radial load resistance. For high-wire rolling mills with large rolling force, high-viscosity lubricating oil is usually used as the lubricating medium. This kind of sliding bearing with lubricating oil as the medium is called oil film bearing.

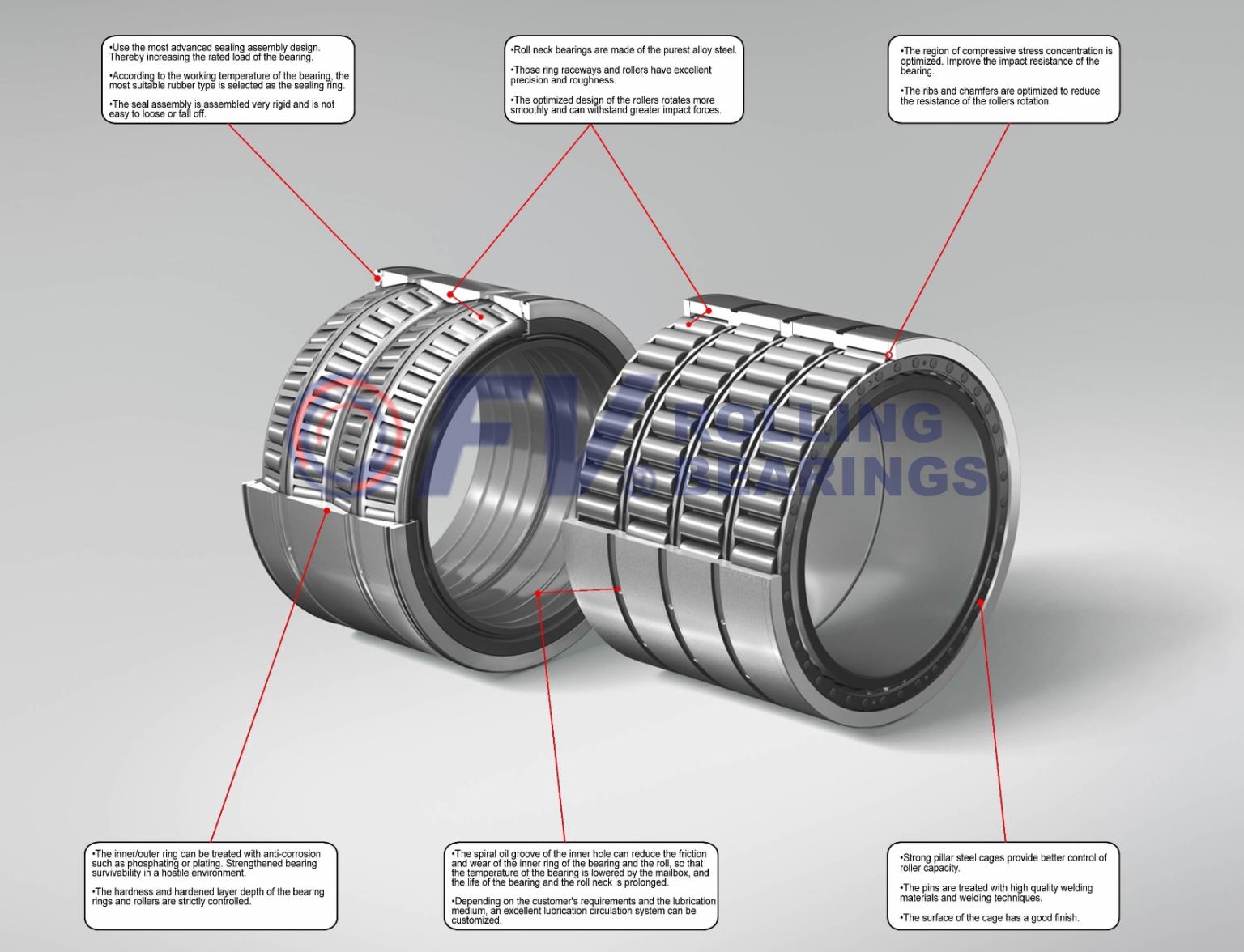

The oil film bearing materials of traditional rolling mills are mostly steel and babbitt metal materials, because babbitt has good inlay and compliance, and has a very low coefficient of friction. Layer babbitt alloy, the advantages of babbitt alloy and copper-lead alloy can be brought into play. We FV oil bearing adopt the alloy welding process. The thickness of the babbitt alloy is 1.5 mm. The price of this thickness is more competitive. Morgan oil film bearings are made of this steel. It well meets the performance requirements of high-speed and heavy-duty high-speed wire rolling mills for oil film bearings, so it is widely used in various high-speed wire rolling mills.

The oil film bearings of high-speed rolling mills are all hydrodynamic bearings, and their working principle is: during the rolling process, the roll journal is forced to deviate from the center of the oil film bearing due to the action of the rolling force, so that the gap between the oil film bearing and the journal forms two areas , one is called the divergence zone and the other is called the convergence zone. After the lubricating oil enters the oil film bearing with the help of the pressure of the oil supply system, the rotating journal brings the lubricating oil with a certain viscosity into the convergent area and the divergent area.

The main feature of Morgan's fifth-generation high-speed wire rod mill is high speed and heavy load. Based on this feature, it requires oil film bearings to have the following characteristics:

1, The oil film bearing has a good heat dissipation capacity, because high-speed operation will definitely bring about an increase in temperature;

2, The oil film bearing must have a certain self-aligning ability, because the heavy load will cause the deflection of the journal;

3, The oil film bearing has a certain ability to resist deformation, because the heavy load will cause the deformation of the inner surface of the oil film bearing.

At present, domestic wire rod mills with high rolling speed can be produced independently, but some parts still need to be imported from abroad, Morgan Bearings is one of them. It can be seen that there is still a certain gap between my country and foreign countries in the field of Morgan bearings. Based on this situation, some well-known domestic bearing manufacturers have devoted themselves to the study of oil film bearings, and have made great breakthroughs, making domestic oil film bearings have a place. Luoyang FV is one of the manufacturers who study oil film bearings. If you have any inquiry, please contact us.

Scan the QR code and push it to your mobile phone for access.

Copyright statement: This article is published by BLOG - FV BEARING INDUSTRIES, if you need to reprint, please indicate the source.