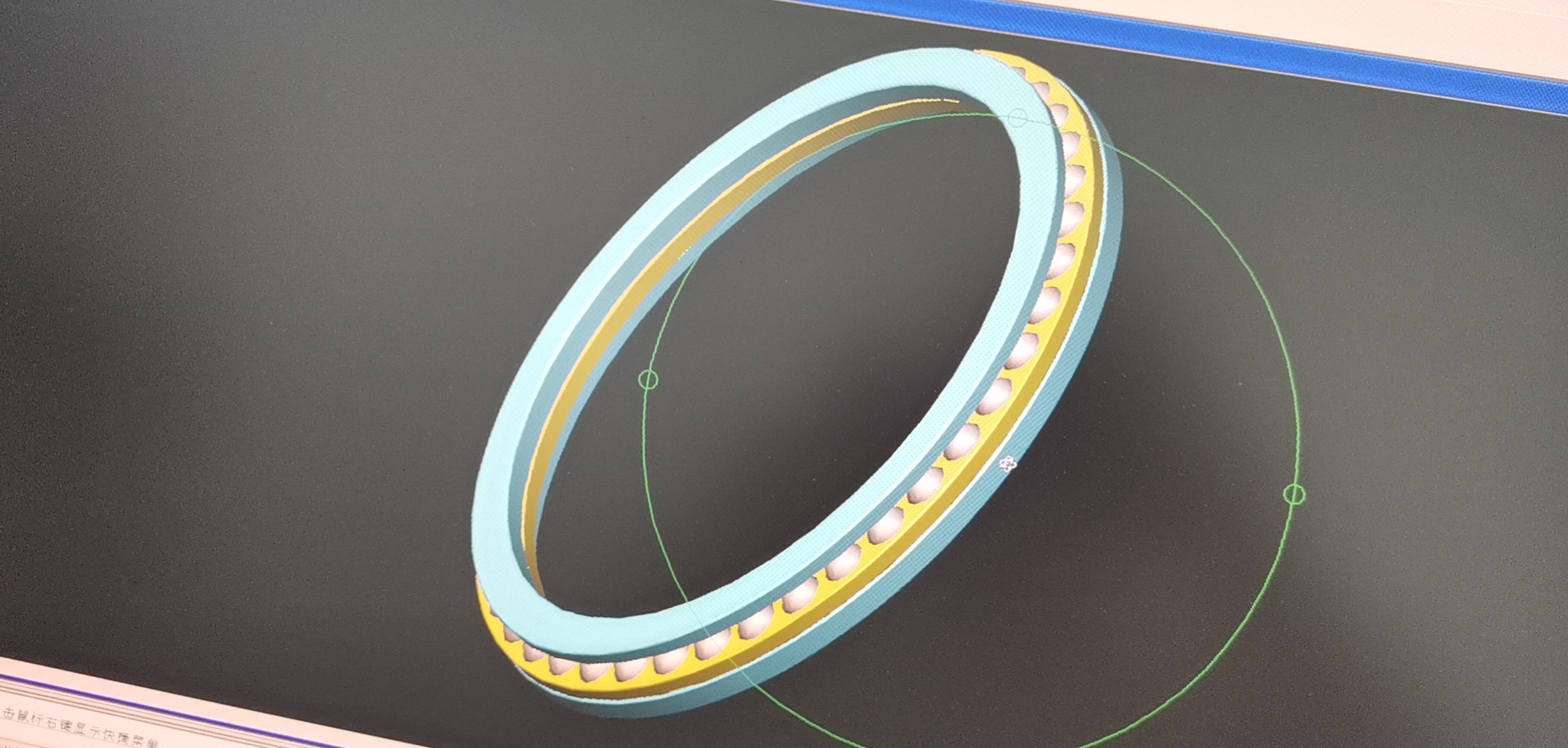

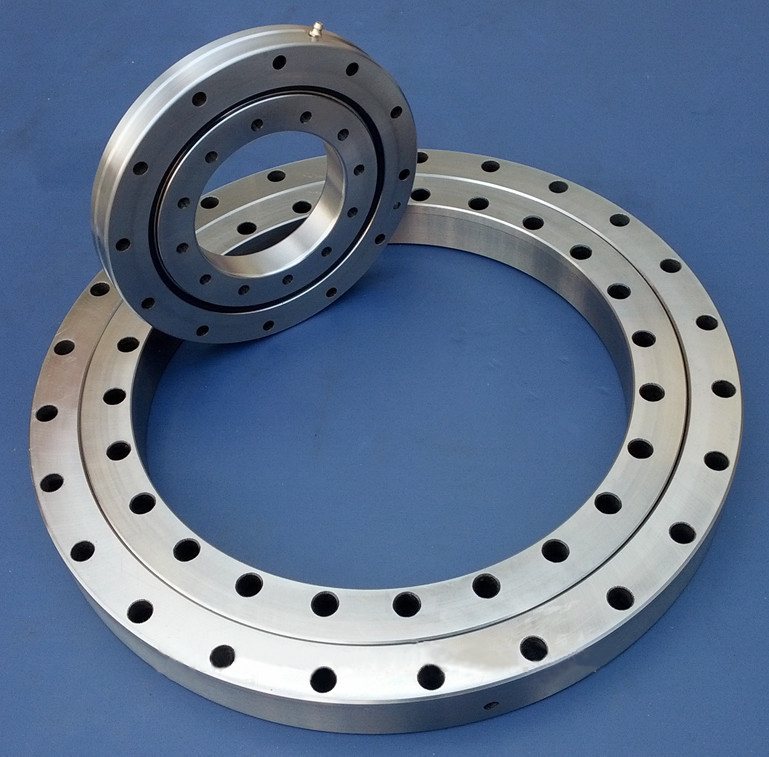

How to Deal with Small Holes on the Surface of Crossed Roller Bearings?

On the surface of crossed roller bearing rings, single or multi-point black dot holes are often found. Sometimes we mistakenly think it's because of material defects, but it's not. These small holes occur on the surface of the ring, so it is also called small hole corrosion, which is localized corrosion of the surface. Then, how are the small holes on the surface of these bearing rings formed, and how should we deal with these small holes?

The formation principle of small holes: The reason for the damage of the crossed roller bearing is that the metal surface of the bearing has a large composition change, non-metallic inclusions, foreign matter adhesion, mechanical damage, cracks in the oxide film and other chemical or physical properties damage. After the bearing metal surface is damaged, its surface is in an active dissolution state, which is an irreversible reaction.

Characteristics of small holes on the surface of crossed roller bearings: Longitudinal dissection of the point defects in the small holes on the surface of crossed roller bearings, observed under a microscope, it is found that the cross-sectional shape of the corrosion hole is corroded perpendicular to the surface. The corrosion of the small holes not only affects the accuracy and surface roughness of the crossed roller bearing, but also reduces the service life and leads to the damage of the bearing, which should be paid enough attention.

Once pinholes appear, here are some easy ways to deal with them:

1. When small holes are formed on the surface of the crossed roller bearing, an appropriate amount of grinding should be used, the corrosion holes should be polished as much as possible, and the small holes should be smoothed at the beginning of corrosion without leaving residues;

2. Anti-rust liquid can be sprayed on the bearing surface to prevent corrosion from happening again.

3. Pay more attention to all aspects of production.

4. You can soak the rust-removed roller bearing parts in the anti-rust solution for a period of time.

In fact, the ideal state is not to let small holes appear on the surface of the crossed roller bearing, then we need to do preventive work, such as keep the surface of parts clean, avoid physical and chemical damage, provide a good storage environment for crossed roller bearings, etc. Of course, the above are only theoretical methods, customers will still have various situations in the process of use, you can consult our FV bearing, a professional bearing supplier!

Scan the QR code and push it to your mobile phone for access.

Copyright statement: This article is published by BLOG - FV BEARING INDUSTRIES, if you need to reprint, please indicate the source.