How to Lubricate and Maintain Rolling Bearings on Running?

We all know that the lubrication oil inside the bearing can reduce the frictional resistance when the rolling bearing is running, and can reduce the wear of the rolling bearing. Bearings need to be injected with grease after production, and these greases will be slowly consumed during operation. Therefore, it is necessary to inject fresh grease into the bearing when the bearing is running. So, do you know how to do it? Today FV teaches you a simple method of injecting grease, I hope it will be useful to you. Because proper lubrication and maintenance can prolong the service life of rolling bearings.

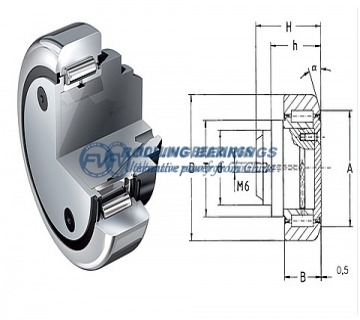

Every time the equipment is shut down for maintenance, the lubrication of the bearings should be checked and replaced or supplemented in time. Remove the old grease, add fresh grease, wipe the grease nipple clean before injecting grease. If the bearing housing does not have a grease nipple, the bearing housing cover or end cap should be opened so that the old grease can be cleaned off and fresh grease of the same type should be injected.

2. Use lubricating oil to lubricate

Regularly check the oil level and oil quality of the lubricating oil. Under normal circumstances, the normal oil level should be within the range of 1/3-2/3 of the oil level marked on the equipment. The oil replenishment method is the oil cup, and the oil level displayed only represents the oil replenishment capacity. When the oil level in the oil cup is lower than 1/4 of its total volume, it is necessary to consider injecting lubricating oil.

Check the lubricating oil method: Take a small amount of lubricating oil as a sample and compare it with fresh lubricating oil. If possible, carry out an oil quality test to ensure that the oil quality is qualified. If the sample looks cloudy, it may be the result of mixing with water, which is often referred to as oil emulsification, and the lubricating oil should be changed at this time. If the sample range becomes darker in color or thicker, it may indicate that the oil has begun to carbonize, and the old oil should be thoroughly cleaned and replaced with a new oil. If conditions permit, it is best to use fresh lubricating oil to flush the oil groove. When changing the oil, make sure that the oil replaced is the same as the previous model.

Oil bath type lubrication system replacement method: If the oil temperature is below 60 ℃, and the lubricating oil is not polluted, the lubricating oil can be replaced once a year. If the oil temperature is 60-100℃, the lubricating oil needs to be changed four times a year. If the oil temperature is 100-120℃, the lubricating oil needs to be replaced once a month. If the oil temperature is above 120℃, the lubricating oil needs to be changed once a week.

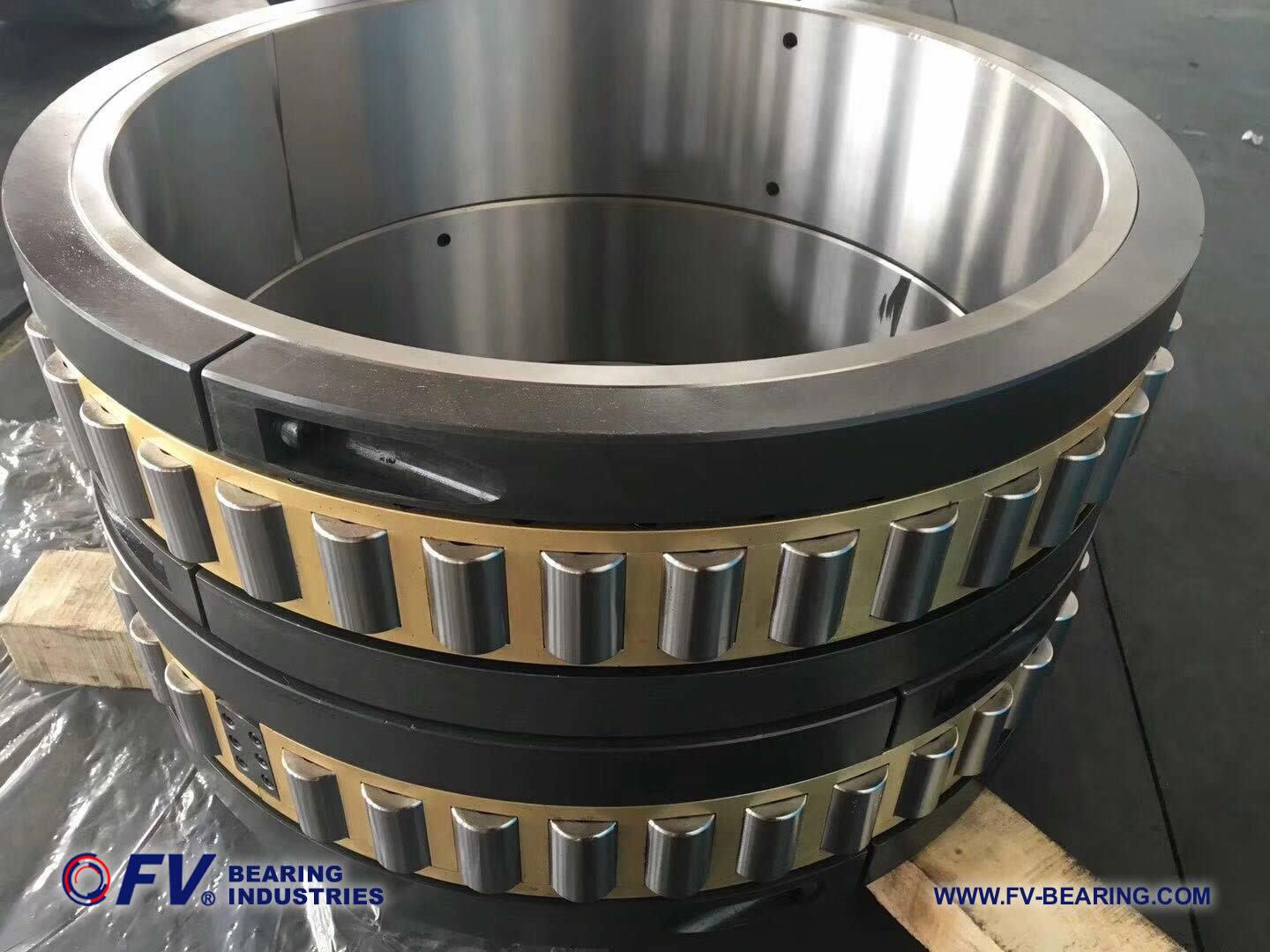

Rolling bearings are precision parts. When we use bearings, we definitely hope that the service life of the bearings will be longer, so correct installation and maintenance are important factors for the long-term operation of the bearings. At the same time, we must pay attention to maintaining the cleanliness of the bearings. Bearings must be protected from contamination and moisture, and must be properly mounted and lubricated. The long-term operation of the bearing is related to many factors, and we must do a good job in every link. If you have questions about lubrication, please contact us FV Bearings.

Scan the QR code and push it to your mobile phone for access.

Copyright statement: This article is published by BLOG - FV BEARING INDUSTRIES, if you need to reprint, please indicate the source.

本文链接:https://blog.fv-bearing.com/Blog/How to Lubricate and Maintain Rolling Bearings on Running?/