How to prevent the wear of rolling mill bearing?

For the metallurgical industry, the loss of many components is very alarming, and rolling mill bearings are one of them. Because the working environment of rolling mill bearings is harsh, the bearing loads are large, and they are subjected to strong impact forces, so rolling mill bearings are particularly vulnerable to damage. For steel mill users, it is necessary to choose a bearing manufacturer with good quality and competitive price. Today we FV will teach you how to avoid the damage of rolling mill bearings.

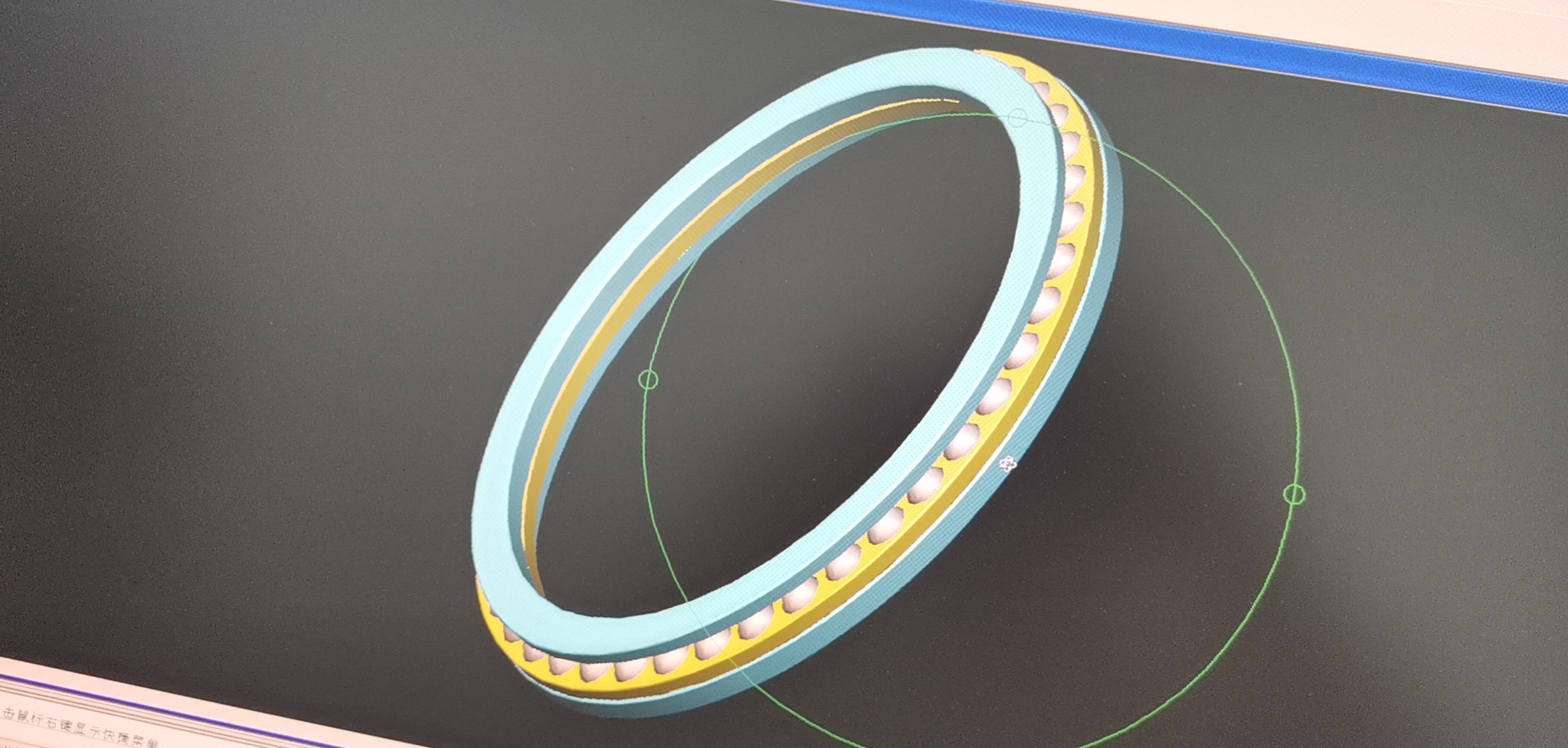

First, choose a bearing manufacturer with reliable quality. The quality of roll neck bearings on the market is different. Different materials, different production processes, different designs, and even different lubricating greases will make bearings perform differently during use. If the quality of the selected roll mill bearing is not good, the bearing will be damaged or worn quickly when it is under load, and this wear will increase with use. The bearing quality of the world-class well-known brand is indeed very good, but the price is not cheap. Luoyang FV is a professional rolling mill bearing manufacturer. We are committed to the design, production and sales of rolling mill bearings. Not only can we produce standard models to replace internationally renowned brands of rolling bearings, but we can also make design modifications to customizes the bearing suitable for the customer.

Secondly, choose high-precision and suitable bearings. After the shaft and the rolling bearing are installed, friction occurs, especially when they rotate. The more severe the friction, the deeper the bearing wear. These wear and tear are usually caused by substandard bearing accuracy; or deformation caused by overheating of the bearing, or it may be caused by factors such as rough surface workmanship of the rolling bearing and low quality of the lubricating oil used. Therefore, you must choose high-precision bearings, and the bearings should be suitable for your own machinery and equipment.

The four-row cylindrical roller bearings and four-row tapered roller bearings produced by Luoyang FV are generally made of high-quality carburized steel, such as TIMKEN3311, which can meet the requirements of high-quality customers for high-quality bearings. At the same time, we can also help customers choose models, customize bearing models, etc., and our prices are very competitive. Welcome to contact us!

Scan the QR code and push it to your mobile phone for access.

Copyright statement: This article is published by BLOG - FV BEARING INDUSTRIES, if you need to reprint, please indicate the source.

本文链接:https://blog.fv-bearing.com/Blog/How to prevent the wear of rolling mill bearing?/