Do you know the Metamorphic Layer of High Wire Rod Rolling Mill Bearings?

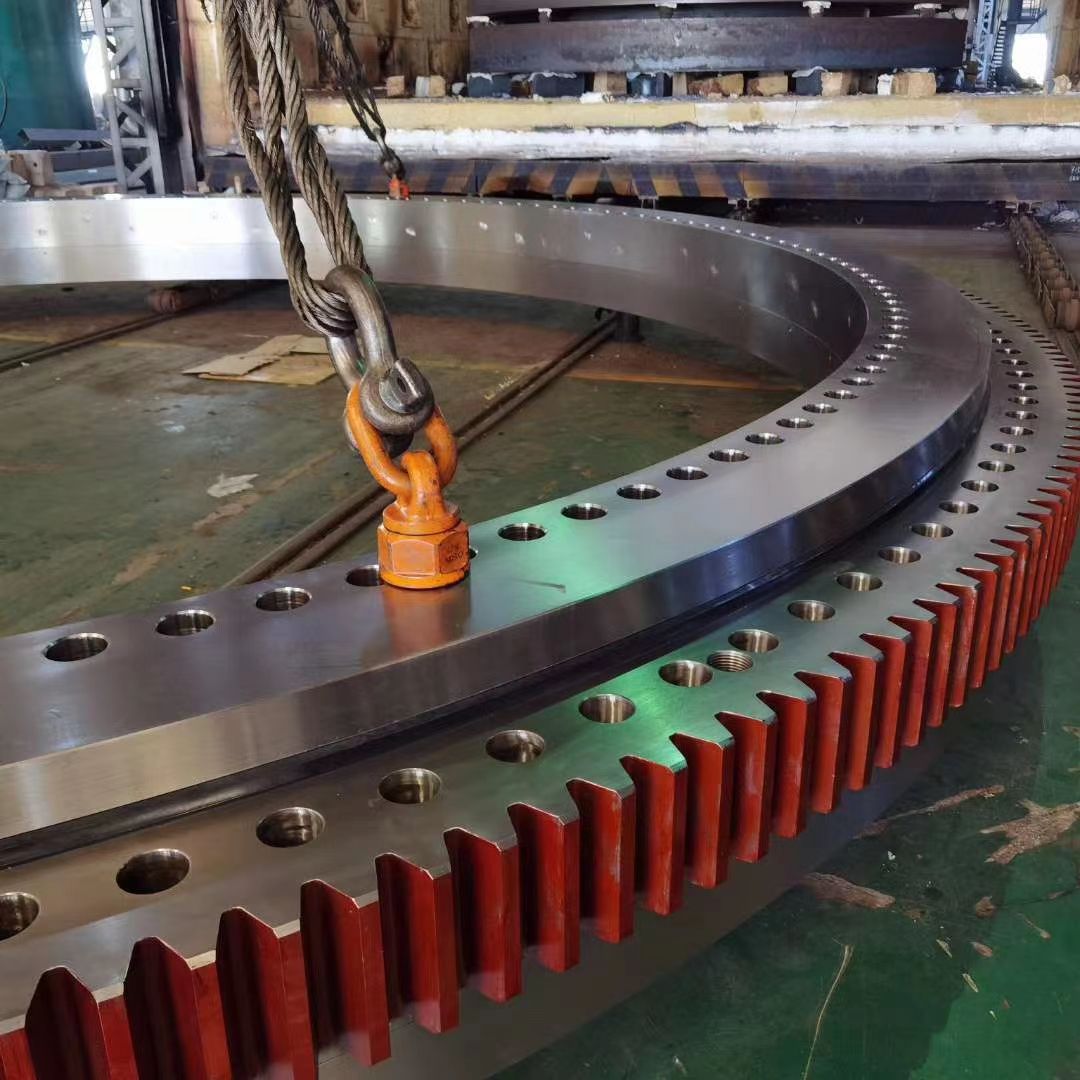

High-speed wire rod rolling mill bearings are very important roll neck bearings, and have high requirements for bearing materials and production processes. However, the high-speed wire rod mill bearing is still a bearing with relatively large consumption. One cause of bearing failure is related to the metamorphic layer of the rolling bearing. Today, Luoyang FV will talk about what role this metamorphic layer plays in the use of bearings.

During the grinding process of rolling mill bearings, the working surface of the bearing will be subjected to a number of different forces, causing changes in its surface layer, and these changes will affect the operation of the entire bearing. These forces include cutting force, compressor and friction force, all of which will make the surface layer of high wire rolling mill bearing form a plastic deformation layer and a work hardening layer, which is what we call a metamorphic layer. The typical hazard of this metamorphic layer is that the residual stress of the bearing surface layer changes. Moreover, such a metamorphic layer is not fixed, it will increase with the increase of grinding degree. At the same time, temperature, hardness, etc. are also one of the factors that affect the size of the metamorphic layer, which will promote the premature failure of the high-speed wire rolling mill bearing. Therefore, users of rolling mills should be aware of the importance of this aspect and the hazards it brings.

Luoyang FV Bearing is mainly engaged in rolling mill bearings, including high-speed wire rod rolling mill bearings, hot rolling mill bearing, cold rolling mill bearing and other production lines. The products involve four-row cylindrical roller bearings, four-row tapered roller bearings, deep groove ball bearings, spherical roller bearings, thrust Bearings etc. Not only standard bearing models can be produced, but also non-standard models can be produced according to the specific needs of customers.

Scan the QR code and push it to your mobile phone for access.

Copyright statement: This article is published by BLOG - FV BEARING INDUSTRIES, if you need to reprint, please indicate the source.